Executive Summary

AI and cloud growth are driving MW-scale backup power demand. FAME B100 enables ultra-low-carbon resiliency, provided that fuel chemistry risks are met with rigorous engineering.

Strategic Context

Data centers are now treated as Critical National Infrastructure, with Tier III–IV uptime expectations and 96-hour+ continuous backup power capability.

Hyperscale and AI loads push IT density beyond 20 kW per rack, driving total site backup requirements into the 10–100 MW class.

Why FAME B100?

FAME B100 delivers verified 94%+ CO₂ and 95%+ criteria pollutant reduction vs. fossil diesel, unlocking powerful regulatory and ESG value.

In LCFS and IRA 45Z environments, B100 becomes a financial asset, not just a fuel, generating recurring carbon credit and tax credit value.

Key Insight

FAME B100 is not a drop-in fuel like HVO. It becomes Tier IV-feasible only as part of an integrated system:

- High-redundancy Fuel Conditioning Management (FCM)

- Mandatory dual-fuel start/purge

- Thermal management + weekly rotation

Engineering Feasibility – B100 in Tier IV Environments

FAME B100 is conditionally feasible. Reliability depends on actively engineering out its oxidation, cold-flow, solvency, and microbial risks.

Fuel Chemistry Risks

Oxidation & Storage Instability

Conventional B100 can go out of spec within 4–6 months. The NZI design uses 168-hour inventory with continuous rotation, effectively eliminating long-term oxidation as a failure mode.

Cold-Flow / Gelling

Elevated cloud point (up to ~16 °C / 61 °F) demands active, redundant tank and line heating, maintaining fuel 5–10 °F above CP at all times.

Solvency & Material Compatibility

B100 immediately mobilizes legacy sludge and attacks non-compatible elastomers. System design includes:

- Pre-cleaned tanks + continuous polishing

- Upgraded seals and hoses

- Accelerated filter replacement program

Fuel Conditioning Management (FCM)

The fuel system is transformed from passive storage into an active, redundant Fuel Conditioning Management (FCM) plant.

Core FCM Functions

- Continuous filtration & water separation

- Automated biocide and water-controller dosing

- Redundant thermal management (tanks + lines)

- Automated switchover to D2/HVO contingency tank

Reliability is enforced via an FQM SLA: proactive testing, component replacement, and guaranteed weekly stock rotation.

Integrated System Design – Generators, FCM & Co-Location

A pre-engineered “Guaranteed Green Resilience Ecosystem” that bundles MW-scale gensets, B100-ready fuel systems, and NZI monetization into a single offer.

Generator Platform

MW-class diesel generator platforms (e.g., Cummins Centum, Generac, Cat DCP-rated sets) are configured for high-concentration biofuels under OEM-approved B100 protocols.

Dual-Fuel Mandate

Start and stop cycles are performed on HVO or D2. B100 is purged from injectors and rails before cool-down, protecting high-tolerance components from corrosion and gelling.

Objective: Tier IV reliability without voiding OEM warranties.Co-Located Production

The FAME plant is physically co-located with the data center, supplying ~120,960 gal of B100 through a rolling 7-day inventory.

This turns the fuel from a long-term storage liability into a short-cycle logistics asset, tightly coupled to data center load and testing regimes.

Regulatory & NZI Advantage

B100’s 95%+ reduction in criteria pollutants simplifies air-quality permitting and reduces community opposition to large stationary diesel assets.

Coupled with LCFS and IRA 45Z, the system becomes a net revenue contributor over its life, offsetting increased CAPEX and OPEX.

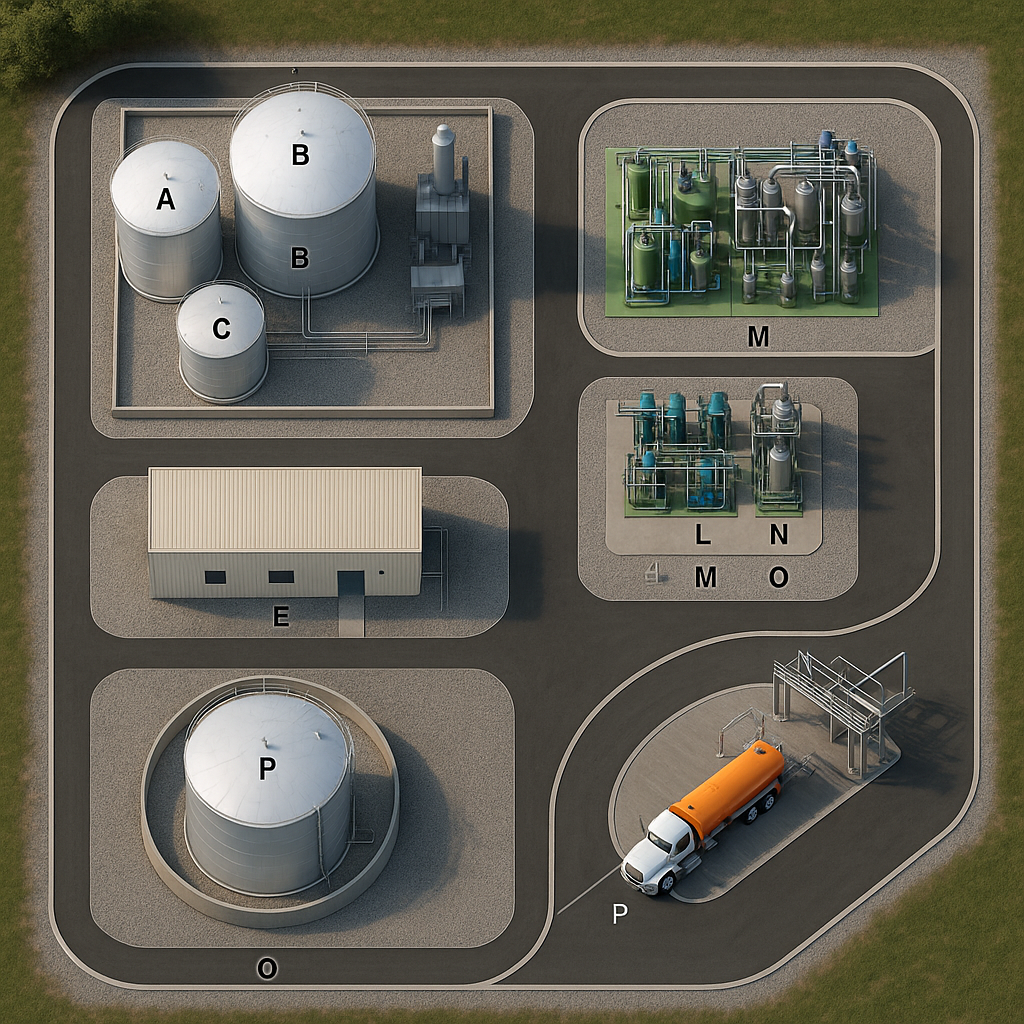

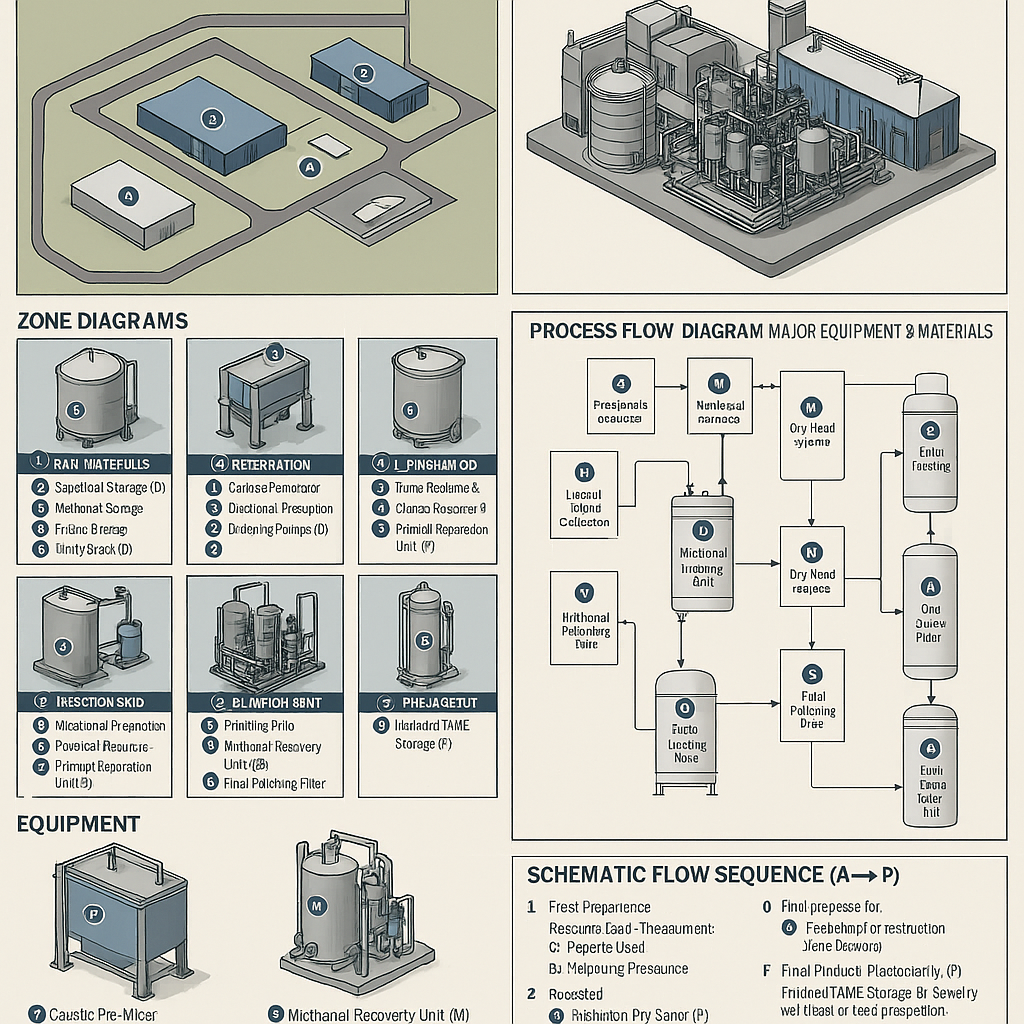

Plant Visuals – Process & Storage Design

The following imagery illustrates the FAME B100 production train, feedstock handling, polishing/filtration, and storage design used in the NZI concept.

Ultrasonic Reaction Skid

Process intensification for continuous transesterification and reduced reactor volume.

Process intensification for continuous transesterification and reduced reactor volume.

Dry Wash System

Eliminates aqueous wash streams; supports NZI water and waste objectives.

Eliminates aqueous wash streams; supports NZI water and waste objectives.

Adsorption & Polishing

Final polishing and contaminant removal upstream of long-term storage and FCM.

Final polishing and contaminant removal upstream of long-term storage and FCM.

NZI Pitch Deck – Download

Full investor-ready presentation of the FAME B100 NZI concept, including engineering architecture, financial modeling, and deployment roadmap.

NZI pItchdeck.pdf

A complete pitch deck summarizing the feasibility study, Tier IV engineering approach, co-located plant design, and the LCFS + IRA 45Z monetization strategy.

Upload NZI pItchdeck.pdf to the same folder as this page on DreamHost (no name change needed). The button above will then serve the file directly.